In MIG welding, a cylindrical steel wire or electrode is fed from the welder through a liner and out of the machine’s gun to form a contact tip.

The welder can use power to heat the metal wire such that it becomes adhesive and able to form bonds. When doing this, the inert gas is added into the liquid metal; this is for protecting the liquid against the chances of it infusing with any harmful atmospheric substances.

Using the melted metal, two metal pieces can be joined as they pass through the welding gun. Using MIG welding, you’ll find that the welding process is much faster than traditional arc welding methods that require welding rods. The easiness of this process makes it so that different skill leveled users can use this tool for a wider variety of welding jobs.

There are a few things that you should keep in mind while shopping for a MIG welder, and in this next section we’ll go over some of them:

Power

One of the very first things that you need to do when trying to purchase a new welder is considering the output of power. For home projects that use thin metals, you could probably get by with 100 amps. However, if you think that you’re going to need to weld thicker metals, then you might want to go up to 140 amps.

This increase in power might cost you some more money, but it will be worth it in the long run.

Wire Feed Speed

The welders feed rate is just as significant as the power of the machine. The feed speed tells you the rate at which the MIG wire is fed into the gun from the machine.

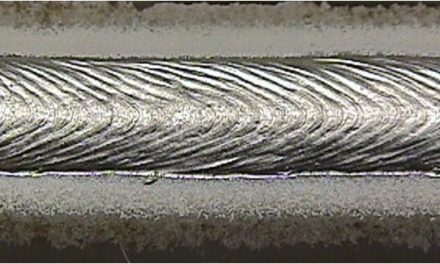

If the feed speed is slow, then the wire will be gone the second that it comes in contact with the metal – which creates an uneven and ugly weld. If the feed speed is faster than it should be, spatter will occur because the wire will reach out from the gun before you can apply it to the metal.

Portability

While performance is the most important thing to consider when choosing a MIG welder, you also want to consider the size of the welder as well if you are going to be carrying it around or you have limited space to store the machine. Welders can range anywhere between 40 pounds to several hundred pounds – it all depends on the power and features of the machine.

The portability needs of your new welder is dependent on the kind of welding that you need to get done. If you have to move the welder around a lot, some carts make moving the machine easier.

Lincoln Electric Power MIG 210

This welder is very adaptable and has a strong sheet-metal construction. It’s ideal for jobs in a small shop and at home. This welder can be plugged into any conventional power supply. It comes with a dual voltage input of 120V or 230V. It has amazing arc action with diamond core technology.

It features an easy-turn numeric drive that shows if there is any tension present in the unit. The Lincoln is best suited for beginners and those who are deciding to try welding for the first time. The display is easy to use and set up. The MIG 210 Mp is multi-functional that can be used as a Tig or a stick welding machine.

Pros:

- Comes with a plug-and-play feature

- The digital controls make setup easy

- Large color display guides will help you get through the setup process

- Weighs 40 pounds

- Advanced options and settings are easy to access

- Can be used by a stick or tig welders

Cons:

- Is unable to handle mass production

Hobart 500553 Handler 210 MVP

With the 210 MVP, you have the option of using either the 115V or 230V power input. It doesn’t require additional tools to connect to the power receptacles. The multi-voltage plug makes it easy to connect and use the welder anywhere. This welder is ideal for beginners or professionals.

The free plugin SpoolRunner 100 is excellent for welding aluminum. It has a built-in wire feeder with adjustable tension.

The Hobart, 210 MVP MIG welder, has a powerful output to deal with 3/8 inch mild steel and good enough to control 24 gauge. This welder is easy to connect to the optional SpoolRunner spool gun. It can be used for applications of stainless or mild steel. The welding machine has seven output voltage settings and speed control.

Pros:

- Welding is smooth

- Cost-effective

Cons:

- Short cables

LOTOS MIG175 MIG Welder

This welding machine has significant weld penetration with a wire feed motor system that functions well. It has a 30 percent duty cycle and weighs 85 pounds. It can connect to either 200V or 220V wall outlets and can be easily set up in ten minutes.

The transformer technology has been proven reliable and durable. This particular product comes with free spool-gun.

Pros:

- Temperature controller

- One-year warranty

Cons:

- Shipping only in the U.S.

- Doesn’t work on heavy-duty jobs

Conclusion

When purchasing a new welder, you need to know what requirements you have for your new welder. Knowing what you want and need will help you narrow down your search and ensure that you find the best one for you. Remember to contemplate what you would be using the welder for regularly because you need a MIG welder machine that has enough power to do the jobs that you need to be done.

It takes more money to get more power, but it’s worth it to avoid having to live with an under-powered welder for the work that you need to be done. Also, you should make sure that you know your budget for a welder. Knowing how much you are able to spend while researching keeps you from going carried away by all the various features different models have.