Of course, if you want to become a consistently better welder and develop your skills over time, you’ll also have to consider engaging with training materials.

Most all welding experts will tell you its more about hands-on learning, not reading a welding textbook to learn basic welding skills.

The good news is there is a way you can learning welding techniques and even advanced welding processes with welding simulators.

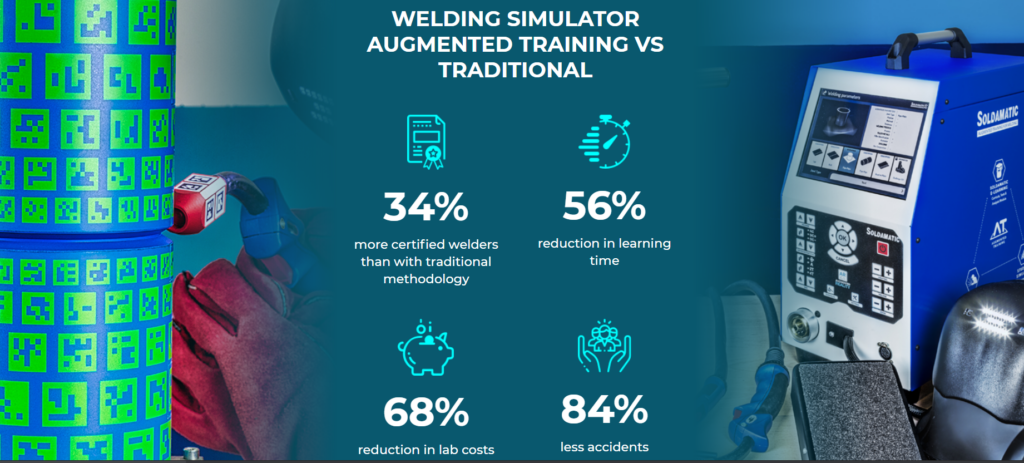

There’s actually plenty of evidence to suggest that augmented reality training and authentic welding simulators deliver superior results to most traditional programs.

According to market-leading providers Soldamatic, augmented reality training drives a significant 56% reduction in learning time, which is beneficial to both new welders and those who are looking to hone and enhance their skills.

With AR welding you can develop and practice new skills at a quicker rate, which is ideal for those who are already working and keen to advance in their chosen career.

AR welding or using a welding simulator also has some other interesting benefits.

Welding Simulators Reduce Accidents

As with any training accidents in the workplace can be significantly reduced. According to Soldamatic, the initial results show AR Welding training is thought to drive an 84% reduction in accidents in the workplace.

Suggesting that augmented reality programs (which introduce interactive and digital elements to a live and real-world environment) create safer and more efficient welders who can optimize the speed of their work without compromising and H&S standards.

Learn Welding Quicker with AR Software

In fast-paced and intense industrial environments where speed and precision can be hard to achieve safely.

AR-inspired software training programs for welders can drive higher rates of data retention over time.

While it's not truly hands-on learning, these welding simulations are pretty realistic. It's the closest you will get to welding, without actually welding.

AR certainly enables young or even experienced welders to experience a different learning cycle that makes information easier to retain, usually through a combination of increased engagement levels and hands-on, practical experience.

AR welding training programs tend to deliver information in a more visual and accessible way, and through a plethora of devices such as smartphones, tablets, and specialist headsets.

Saves on Weld Material Cost

When the price of raw materials goes up, it's difficult to justify practicing with expensive gases and metals. With AR welding. You can practice all day and night and never run out of materials. Just reboot the system and start again.

Those cost of materials really add up quickly. Don't underestimate even scrap metal is worth something.

These virtual reality environments are pretty impressive. You may not be using real materials, but it sure feels like it.

Career Preparation

Even the best welders make mistakes, so when do you know when you are ready for a career in welding. (in the real world)

With a virtual welding simulator, you get real-time feedback.

You can actually compete against yourself and others in your welding scenarios. You'll be able to easily assess how you are doing as a beginner (or experienced) welder.

Learn all types of Welding

With AR welding you can test out different types of welds, get creative, and step outside of your comfort zone. With an AR training tool you can make mistakes. So if you have always wanted to try a particular type of welding or want to test a particular unique joint out from a recent blueprint you received before starting on the real thing. A welding simulator will cut that training time down significantly.

No instructor around to teach you? AR training programs have step-by-step instructions as well.

Onboard New Employees

For the shop owner that wants to onboard new employees to learn from the best and exactly the same each time. NOt only can you create online access, but creating a standalone setup for welding booths or classroom setup with a single simulator pays off quickly.

Imagine how many mistakes or miscommunications happen with new employees. You want to train them properly, but all that practice time is expensive as well.

And if you have ever had a new recruit tell you how “experienced” they were. You can give them a tryout with a welding simulation. Now that will tell you just how “experienced” they truly are.

The Last Word

Of course, it’s unarguable AR welding simulations often need to be tailormade for manual skills and trades such as welding, primarily because specific usage instructions and tips can be assigned directly to physical objects.

Depending on the type of welding simulation needed and level of accuracy of your weld, will determine your virtual reality welding environment.

Not only this, but AR-based welding simulations and training programs take place with physical devices in a safe and controlled location. Because of this, trainees can utilize real tools and equipment in an interactive training setting, which is one the main reasons why AR programs deliver superior results in terms of safety and execution.

Clearly, there are numerous ways in which you can improve your welding skills, from small and incremental steps that enhance your everyday working methodology to long-term training programs that target specific areas of knowledge.

If you are going to pursue a dedicated welding program, however, there’s no doubt that augmented reality programs are far more effective, engaging and capable of delivering superior results.